Digital Twins: Shaping the Future of UAE Warehouse Automation

Digital twins in warehouses are redefining how warehouses operate across the UAE and the wider GCC region. A digital twin is a virtual replica of a real warehouse system that lets businesses monitor, simulate, and optimize operations in real time. By bridging physical and digital environments, digital twins help decision-makers boost performance, reduce errors, and increase profitability.

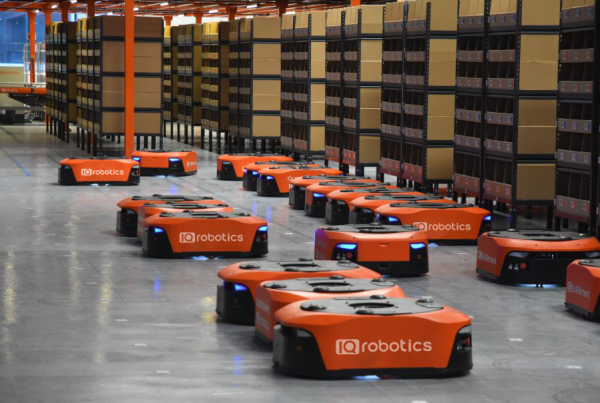

At the forefront of this innovation is IQ Robotics, a leading provider of warehouse automation solutions in the UAE. Its intelligent software combines robotics, automation, and AI-driven analytics to help warehouses visualize and refine workflows before deployment. This ensures every automation investment delivers measurable ROI.

The Role of Digital Twins in Smart Warehouse Automation

Digital twins in warehouses enable operators to simulate, test, and refine processes before implementation. They model robotic movements, conveyor flows, sorting systems, and storage patterns — helping identify inefficiencies early.

Key Benefits:

• Provides full visibility into warehouse operations before physical deployment.

• Reduces risks by identifying inefficiencies in early simulation stages.

• Ensures smooth coordination between automated systems.

• Enhances flexibility and accuracy in high-volume logistics environments.

By using real-time data from sensors and WMS platforms, digital twins predict system behaviour under different conditions. This predictive view makes warehouse automation more accurate, flexible, and error-free, essential for large-scale logistics in Dubai South and JAFZA.

Real-Time Insights for Smarter, Faster Decisions

The real value of digital twins lies in actionable, real-time insights. Every robot, conveyor, and inventory movement generates data that reveals performance gaps.

Warehouse managers can instantly visualize how changes in demand or stock affect workflows. This reduces guesswork and supports informed decision-making focused on measurable outcomes such as faster order fulfillment, fewer errors, and improved system uptime.

Operational Advantages:

• Delivers instant visibility into logistics performance.

• Enables proactive adjustments to meet changing demand.

• Improves order accuracy and reduces downtime.

• Supports continuous improvement through AI analytics.

Digital twins transform traditional operations into AI-enabled smart warehouses, where every process is tracked, analysed, and optimized for the best ROI.

Enhancing Robotics Warehousing Through Simulation

Precision defines robotics automation. Digital twins create a virtual testbed where robots, sorters, and picking systems are evaluated before deployment.

Key Applications:

• Simulates robot movement, load handling, and picking accuracy.

• Ensures coordination among robots, conveyors, and sorters.

• Reduces implementation time and testing costs.

• Validates system reliability before physical rollout.

By minimizing trial-and-error in physical setups, warehouses in Abu Dhabi and across the GCC save both time and capital.

Predictive Maintenance and Continuous Uptime

One of the greatest advantages of digital twins in warehouse automation in UAE is predictive maintenance. These virtual systems continuously monitor robotic equipment, detecting early anomalies before they escalate into failures.

By analysing vibration levels, speed patterns, and power usage, digital twins forecast wear and tear, allowing for proactive maintenance scheduling.

Why It Stands Out:

• Prevents unplanned downtime through early fault detection.

• Extends equipment lifespan and reliability.

• Reduces repair costs and improves ROI.

• Maintains continuous uptime for e-commerce fulfilment operations.

Driving ROI Through Continuous Optimisation

Every automation project should deliver clear, measurable returns. Digital twins make this possible by aligning warehouse performance with business goals.

Key Outcomes:

• Provides accurate data for better financial decisions.

• Improves layout and process efficiency through modelling.

• Cuts Labor costs while increasing throughput.

• Ensures every automation upgrade delivers tangible ROI.

Digital twins in warehouses ensure that every decision contributes directly to profitability — a critical factor in AI logistics and GCC warehousing.

Data-Driven Scalability for Growing Operations

As businesses expand, so should their automation systems. Digital twins simplify scalability by letting teams simulate future changes safely.

They show how adjustments to storage capacity, robotic fleets, or layout design affect throughput and workflow balance. This foresight supports data-driven growth instead of reactive decision-making.

For UAE logistics firms aiming for sustainable expansion, digital twins minimize disruption and ensure performance consistency across facilities.

Conclusion

Digital twins in warehouses are reshaping warehouse automation into a predictive, data-driven ecosystem. By merging virtual simulation with real-time analytics, they help businesses reduce costs, improve efficiency, and maximize ROI.

IQ Robotics leads this transformation in the UAE by enabling companies to simulate success, anticipate challenges, and achieve tangible operational gains. Warehouses that embrace this technology are not just automating — they’re building the foundation for the future of smart logistics in the GCC.

Contact IQ Robotics for a tailored consultation or follow us on LinkedIn for the latest automation insights.

FAQs

1. What is a digital twin in warehouse automation?

A digital twin is a virtual model of a warehouse that mirrors real-time operations. It helps optimize workflows and reduce risk, ensuring better ROI with IQ Robotics’ automation systems.

2. How do digital twins benefit warehouse automation in the UAE?

They simulate layouts, robotics movement, and energy use to identify efficient configurations before real deployment.

3. How are digital twins used with robotics automation?

They let engineers test and fine-tune robotic programs in virtual environments, improving coordination and cutting downtime.

4. Why are digital twins vital for predictive maintenance?

They use real-time analytics to forecast potential equipment failures, enabling proactive repairs that prevent costly breakdowns.

5. Can digital twins support warehouse scalability?

Yes. They model capacity expansions and process changes before implementation, ensuring scalability, stability, and consistent ROI across operations.