Robotics Sortation vs Manual Labor: Who’s Faster?

E-commerce growth across the UAE and GCC has redefined what efficiency means in logistics. Fulfillment speed now determines customer satisfaction, retention, and profitability. Traditional manual sorting—once reliable—can no longer keep up with modern warehouse demands. The rise of robotic sortation systems is changing that, setting a new benchmark for speed, accuracy, and scalability.

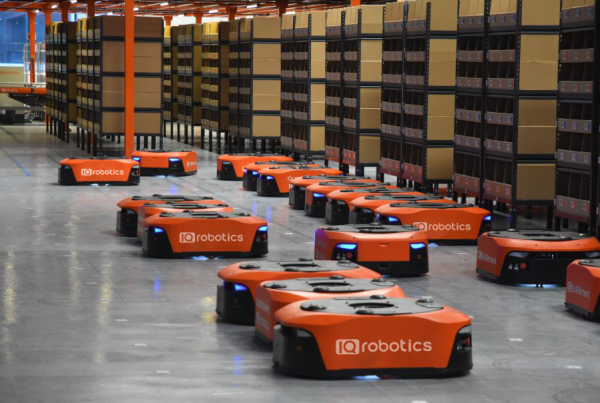

IQ Robotics, a regional automation leader, integrates robotics sortation solutions powered by AI and motion control technology. Their systems automate goods movement and optimize workflows to deliver real-time precision in every fulfillment cycle

How Robotics Sortation Transforms Fulfillment Speed

In every fulfillment center, sorting dictates the rhythm of delivery. Robotics sortation systems eliminate delays from manual handling and keep operations consistent round the clock.

Key Advantages:

• Detect and sort parcels with real-time vision and sensor technology.

• Automate repetitive sorting tasks to handle thousands of orders per hour.

• Reduce idle time and errors caused by manual delays.

• Maintain high throughput even during peak order seasons.

By automating sortation, warehouses can process more orders in less time — achieving faster dispatch and improved customer experience.

Ensuring Consistency and Accuracy at Scale

Unlike manual labor, which is prone to fatigue and inconsistencies, robotic sortation guarantees precision every time. Advanced programming allows robots to adapt to dynamic order flows and SKU changes without interruption.

Performance Highlights:

• Maintains consistent speed and sorting accuracy.

• Adapts automatically to different product sizes or labels.

• Minimizes human error and rework.

This reliability ensures that large-scale operations across Dubai, Abu Dhabi, and the GCC meet global delivery standards while optimizing fulfillment costs.

Boosting Productivity with Warehouse Robotics

Modern warehouse robotics operations depend on robotics for more than just sorting. These systems manage picking, stacking, and labeling — all while coordinating seamlessly through centralized software.

Core Functions of Warehouse Robotics:

• Executes repetitive, high-volume tasks with precision.

• Integrates with Warehouse Management Systems (WMS) for end-to-end visibility.

• Frees human staff for supervisory and quality control roles.

• Enhances coordination between different automation systems.

The synergy between robotics and human oversight leads to operational excellence, minimizing downtime and maximizing ROI.

Energy Efficiency and Scalable Automation

Scalability defines the success of automation. As order volumes grow, robotic sortation systems can expand modularly without major infrastructure changes.

Key Benefits:

• Adds new robotic units easily to increase throughput.

• Consumes power only during operation, lowering energy costs.

• Recycles energy during idle or braking periods.

• Supports long-term sustainability goals.

For warehouses across the UAE, this flexibility enables cost-efficient scaling, turning automation into a sustainable, future-ready investment.

Manual Labor vs. Robotic Sortation: A Clear Winner

Manual sorting relies heavily on physical effort and timing. Workers face fatigue, shift variations, and risk of errors especially during high-demand seasons. Robotic sortation, in contrast, operates without breaks or fatigue, maintaining steady speed and accuracy across all shifts.

The outcome is not just faster fulfillment but a safer and more predictable workflow.

Safety, Workforce Evolution, and Human Collaboration

Automation does not eliminate jobs it redefines them. Robots handle repetitive or heavy-duty work, allowing employees to focus on technical and analytical roles.

Workplace Benefits:

• Reduces workplace injuries and strain-related issues.

• Encourages upskilling in system monitoring and maintenance.

• Creates a safer, data-driven work environment.

The collaboration between robotics and skilled labor ensures that fulfillment centers remain safe, efficient, and adaptable.

Conclusion

In the battle between robotic sortation and manual labor, automation wins decisively offering unmatched speed, reliability, and scalability. With intelligent sortation and energy-efficient performance, warehouses can now deliver at e-commerce speed while reducing costs.

IQ Robotics empowers businesses across the UAE and GCC to transform their logistics performance through innovative automation.

Contact IQ Robotics for a tailored consultation or follow us on LinkedIn for more insights into warehouse automation and digital transformation.

FAQs

1. What is a robotic sortation system?

A robotic sortation system uses AI, sensors, and motion control to identify, classify, and direct packages automatically for faster fulfillment.

2. How do robotic systems improve fulfillment speed?

They eliminate repetitive manual sorting and operate continuously without fatigue, ensuring consistent, error-free deliveries.

3. Are robotic sortation systems cost-effective?

Yes. While the initial cost is higher, automation reduces labor expenses, downtime, and operational inefficiencies over time.

4. Can robots work alongside human staff?

Absolutely. Robots handle repetitive and heavy tasks, while employees focus on oversight, analytics, and system optimization.

5. What support does IQ Robotics provide?

IQ Robotics offers complete installation, training, and ongoing maintenance to ensure smooth and scalable automation performance.