An Introduction to Robotic Sortation Systems

The modern supply chain is no longer a straight-shot pipeline; it looks more like an intersection on a crowded highway, in which thousands of vehicles must move seamlessly every day, with no delay. Warehouses are the stage for these key crossroads, and if systems of sorting are not effective, this can spiral to calamity. Traditional manual sorting is no match for the fast and furious needs of today’s e-commerce, which is why many businesses are turning to advanced Warehouse Automation Solutions. Robot sortation systems are at the heart of these innovations, strengthening warehouse operations to a new level of efficiency and accuracy.

The importance of automation in today’s warehouses

Every day, e-commerce behemoths, logistics operators process packages by the millions. Consider peak periods such as Black Friday, or holiday shopping — manual labor simply cannot keep up with that burst. Automation and robotics offer the speed, accuracy and reliability required for continuous operations.

How warehouse sortation tech has evolved

Human workers along both sides used to be commonplace on the conveyor belts not so long ago. The movement, picking and sorting of parcels was done manually by workers. It worked, more or less, but it was slow and riddled with errors. Warehouses increasingly moved to semi-automated systems over the years. Robotic sortation systems are what’s coming next: a colossal step forward that marries robotics, AI, and smart sensors to generate high-speed, faultless outputs.

What Do You Mean by Robotic Sortation Systems?

The nuts and bolts of robotic sortation systems Robot sortation systems at their essence, are automated machinery built to recognize, sort, and route products throughout a warehouse to the desired destination. They use cutting-edge technologies, including AI algorithms, barcode scanners, ultra-light robots, RFID tags, and machine vision, to complete their missions fast and accurately.

- Definition and key components

- A typical robotic sortation system comprises:

- Robotic arms or mobile robots to manage goods.

- Sensors and scanners for product recognition.

- Conveyors and chutes to move things.

- Software connected with a Warehouse Management System (WMS).

Robotic Vs. Conventional Sortation

Conventional systems rely too heavily on human involvement, reducing output and driving up costs. Robotic systems, meanwhile, are quicker, more precise and can operate 24/7, with less downtime.

Real-world robotics sortation use cases

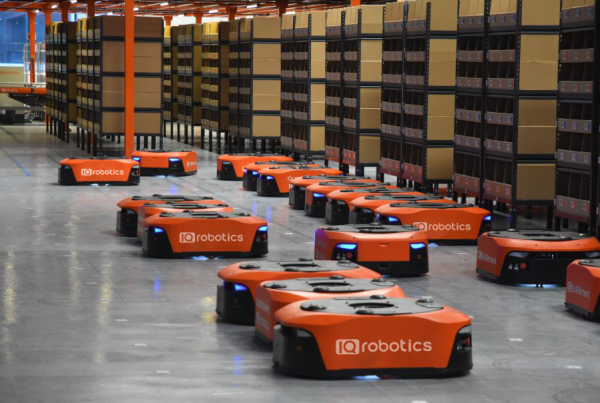

Ever seen a robot racing across a warehouse floor with bins in tow? That’s an autonomous mobile robot (AMR) sorting products into bins. Another is a robotic arm grabbing items off a conveyor and putting them into shipping containers. These are already being employed by Amazon, DHL, Alibaba.

How an Automated Sortation System Works

Robotics Warehousing Automation is not just about robots moving around. It’s a carefully choreographed dance of hardware and software, not unlike an orchestra in which each instrument has a part to play. Sensors, scanners, and AI algorithms, Think of the process as an orchestra: sensors, scanners, and AI play in harmony, directing robots to place each item exactly where it belongs. Here, AI algorithms determine where each object should go with the goal of speed and correctness.

Part played by conveyors and robot arms

Conveyors move products across the warehouse. Robotic arm or shuttle follows and picks and/or places products into bins or onto pallets as directed by the WMS.

Interfacing with warehouse management systems (WMS)

The WMS is the brains of the system and it signals to robots in real-time. It may handle inventory, track orders and ensure that items flow smoothly from receiving to storage to dispatch.

Advantages of Employing Robotic Sortation in Warehouses

The point isn’t that humans are being replaced by robots to sort this stuff — (though robots are being used). It’s that sortation centers equipped with robotics are able to take sortation to new levels of efficiency.

Increased efficiency and speed: Robots sort thousands of packages an hour in a way human worker could never do without exhaustion or errors.

Lower Labor Costs and Reduced Errors: Automating routine work for companies means that they can slash labor costs while eliminating mistakes that arise from human fatigue or negligence.

Space optimization and scalability: Robots don’t require big walkways or breaks. They enable the warehouses to be designed more densely, to store more and to scale operations more readily.

Enhanced safety and sustainability: Robots eliminate the need for people to do physically difficult work, reducing accidents in the workplace. What’s more, most robotic setups are environmentally friendly and energy efficient.

Robotic Sortation System Categories: Robotic systems are not one-size-fits-all. Different warehouses require different technologies.

Automated guided vehicles (AGVs): AGVs move along fixed paths (such as magnetic strips) to move goods around. They are dependable but less flexible than newer alternatives.

Autonomous mobile robots (AMRs): AMRs move about the warehouse unencumbered by sensors or AI and respond to changes in the warehouse surroundings. Slightly as in that order of magnitude, and yes, as in the case of the dominant type of flexible sortation right now.

Robotic arms and picker stations: These machines are really good at picking up and putting down things quickly and accurately. They’re ideal for high-throughput operations.

Hybrid sortation systems: Most warehouses rely on a mix of conveyor, AGV AMR, and robot arm in order to achieve the highest degree of optimization and reinforcement of the various applications.

Obstacles to Robotic Sortation System Application

However, robotic systems have their obstacles. Robotic sorting is the problem:, robotic sortation is extremely costly, which is inhibiting for SME’s. But the return on investment in the long run usually pays off the cost. Robotics don’t always naturally plug and play with legacy systems unless they’re updated or you make some type of work-around. Employees must be trained to operate next to robots, and change management is key to successful deployment.

- Maintenance and support requirements

As with all technologies, there are also maintenance and technical skills involved in robotic systems.

Future of Robotic Sortation Systems

The world is bright for robotics-inclined warehouses. Integration of AI and machine learning AI and machine learning are crucial elements in predictive analytics. AI will not just run the operations: it will predict demand, optimize workflows and do so before problems start to appear. The result will be a fully integrated smart warehouse ecosystem in which thousands of IoT sensors are attached to every item of machinery. Instead, the robots of tomorrow will be built with sustainability in mind, incorporating energy-efficient motors and recyclable materials to minimize their carbon footprint.

- Implementing Robotic Sortation into Best Practices

- Implementing robotics requires careful planning.

- Warehousing needs factor prior investment

Don’t charge into it Spend time analyzing your warehouse operations to determine where robotics will have the highest impact. Work with partners who know your business and can offer the most flexible solutions. Begin with small experiments, test for performance, then go wider across your warehouse to limit risks. When in place, track performance often and maximize processes for the greatest ROI.

Conclusion

Despite upfront investment and integration hurdles, robotic sortation delivers long-term gains in speed, accuracy, and sustainability. Companies across the UAE and GCC are adopting these systems to future-proof operations

In the UAE, where e-commerce and last-mile logistics are expanding rapidly, robotic sortation enables fulfillment centers to process thousands of orders during peak seasons such as Ramadan and Black Friday

Stay Connected To Us

Discover how IQ Robotics’ sortation solutions can help you cut costs and scale operations. Contact us for a consultation or follow us on LinkedIn for case studies and tips