The logistics industry is booming in the region. Today, new tools are transforming every part of the supply flow. Today, most businesses simply cannot run without warehouse automation systems UAE as they enhance speed and accuracy. This change accommodates growing demand and complicated trade routes. More changes are on the way, and as 2025 looms, they will further dictate how warehouses operate in the years to come.

Increased Demand for Automation.

There is also an ever-increasing demand for faster delivery. Warehouses need to be able to move goods with reduced delays. Teams can be relieved of this pressure by automation systems. It trims errors and helps with steady workflows. Today, many sites concentrate on the most basic of layout planning. They also explore “elastic” solutions — where capacity scales with usage. This transition provides a solid platform for sustainable long-term growth. The rapid growth of the region makes automation essential to keeping up with work.

Development of Smart Warehouse Technology

A lot of warehouse work is now guided by digital tools. Smart warehouse technology know-how for the warehouse keeps staff in constant touch with goods. It provides them with visibility into the daily flow of work. It also facilitates forecasting demand cycles. This knowledge is to reduce waste and optimise storage usage. Greater numbers of sensors are now linked to cloud systems. These tools connect data with teams in seconds. That helps crews address problems before they expand. It’s also better for faster decision-making.

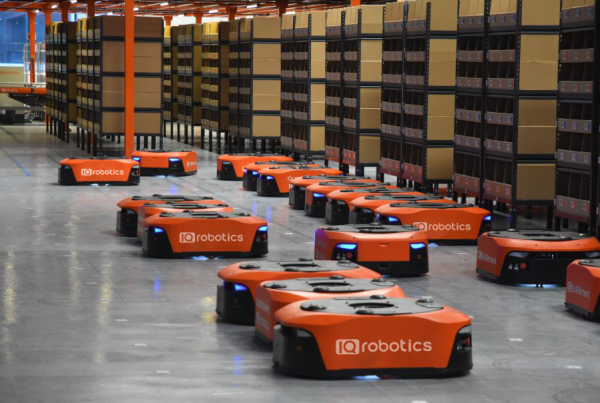

Robots That Will Do Your Work: The new robots of daily work.

That goes beyond automation of simple tasks. Now, many teams are pushing at the frontiers of robotics. Warehouse automation robots— for heavy lifting and a smooth stride—are transforming industries. These robots are also useful to minimise manual strain. They transport goods on floors with firm control and aid teams in staffing complex work. This manoeuvre saves time and minimises risk. Robots now learn from historical data, ensuring every run is smoother than the next. A leading Robotics Company in Dubai is pioneering such innovations, integrating advanced automation systems into modern industries. The growth of robotics will redefine working spaces and layout design.

Emphasised adaptable storage solutions

Storage design is now adjusting to market requirements. A lot of warehouses retrofit racks and zones. These changes make it easier for teams to move goods with fewer steps. Dynamic saves both fast and slow-pick materials. It also allows teams to adapt to seasonal demand. It’s all about free flow from entry to exit. For example, electronics tracking currently arranges the quickest pathway for every item. This creates firm control, the whole way through.

AI and Data Form Makers make fresh decisions with AI and data.

Daily planning now is really connected to AI. It learns from past data and predicts the next move. This assists teams in staffing and stock levels. It also enables teams to sidestep sudden delays. AI tools connect with tracking systems now. Those tools broadcast updates on goods and the health of the machine. That assistance helps keep work afloat. AI also aids in planning for future upgrades. It provides a clear vision in the long term.

Cloud Integration Improves Collaboration

Tools in the cloud now link teams across sites. These tools have simple dashboards with shared data. This allows leaders to monitor orders each hour. It also allows teams to work from anywhere. The cloud integration ensures that it is easy to scale things up. It stores data so it can be secure and remain accessible. This setup is now common for many warehouses. It facilitates the flow of work in the whole supply chain.

Intermediate Application of Automation Patterns

The area’s market is hot and growing. Mid-scale automation is now invested in by many teams. This change in process will allow more secure updates without the same level of risk. Not quite that fast, a cheaper feature of their opponents going out-of-band with contract options. They facilitate gradual increases in output for crews. These updates also reduce downtime. The quicker the task, the more orders throughout the day. The trend will accelerate as more leaders witness the effect.

Growing Demand for Warehouse Automation Systems UAE’s

And, every year, the need for steady and precise tools increases. Nowadays, several companies look into warehouse automation systems UAE in order to achieve the instantaneous targets. These systems help teams operate with less waste. They ensure the goods are transported without danger through all zones. “are also reducing manual labour. When good adopt, the market is stable and predictable flow.

Focus on Workforce Training

Automation does not replace people. It helps people work smarter. Teams will need to figure out how to steer new tools. Training is now all about the basics of teaching. It lets operators monitor problems quickly. It is also what lets them control robots and AI tools. Strong training builds trust. It also helps build safe, stable work zones. It’s all about leverage: With the right skills, teams have more of it. They get bigger and bigger with each new update.

New Tools Reflect Sustainability Aspirations

Now the area has become a mecca for green goals. Warehouses examine energy consumption and waste. Many automated tools save power. Some systems cut down on longer travel distances. These changes cut emissions. And on many sites, smart sensors monitor energy use. This is in favour of concise announcements for growth strategies. Sustainable automation is a theme that will inform many upgrades in the coming years.

Conclusion

The future is looking strong for automated logistics in the area. New levers will help shape how goods travel through each stage. Artificial intelligence, robotics, cloud and smart data will underpin sturdy and safe workflows. And warehouse automation systems UAE will continue to bring stability in the growth. It will enable teams to meet demand quickly and accurately. And as 2025 draws near, automation will be the drumbeat shaping how warehouses plan to work and grow.

Get in touch with us and request a special consultation on IQ Robotics, or browse our LinkedIn to get to know us.

FAQs

1. What is behind the rise of automation in the UAE?

Fast trade routes and flourishing demand spur rapid upgrades.

2. Are robot-run warehouses safe for workers?

Yes, they cut down on heavy lifting and help create safer areas.

3. Do robots replace human staff?

No, robots take care of easy stuff, and staff handle the hard cases.

4. In what way does AI help in the flow of the warehouse?

Above all, AI has gotten good at telling us what’s coming down the pike, raising questions about whether we’re just gambling on our own fates.

5. Does automation reduce delivery time?

Yes - automation eliminates lags and increases order speed.